This is how inventory management

Centralize your entire inventory operation in real-time – so you never over or undersell again.

Avoid cashflow headaches and understock shocks.

Leverage pinpoint accuracy in inventory and order data across all sales channels.

Put tedious, time-consuming inventory tasks on autopilot so you can focus on strategic work that matters.

Consolidate your entire inventory operation into one central hub, simplifying your management processes.

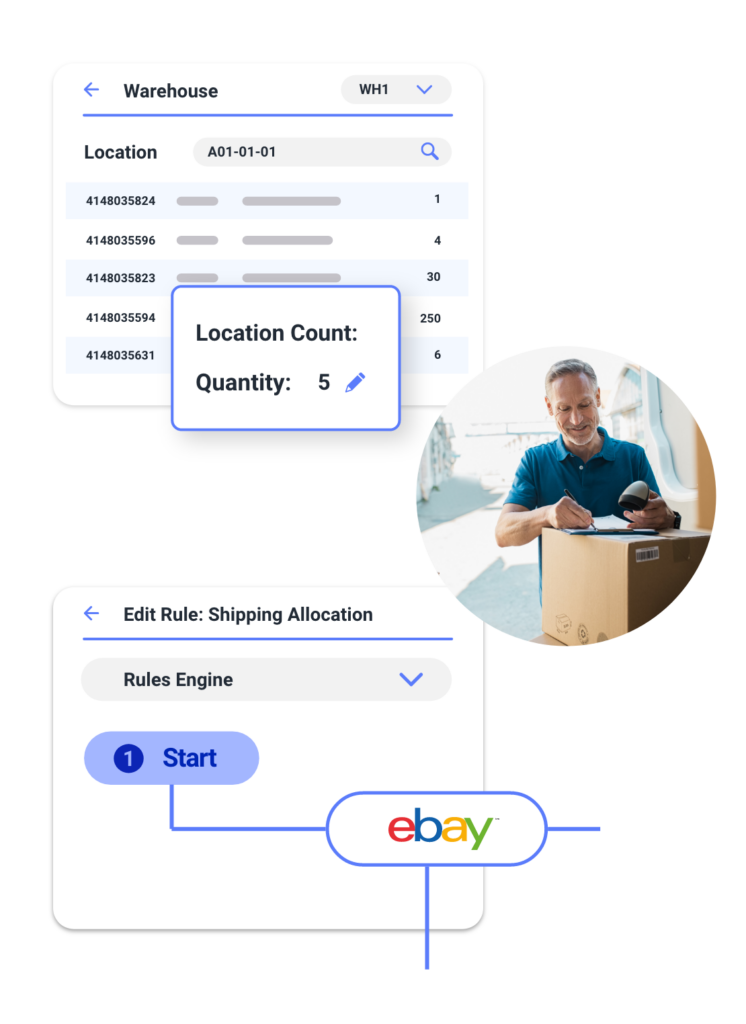

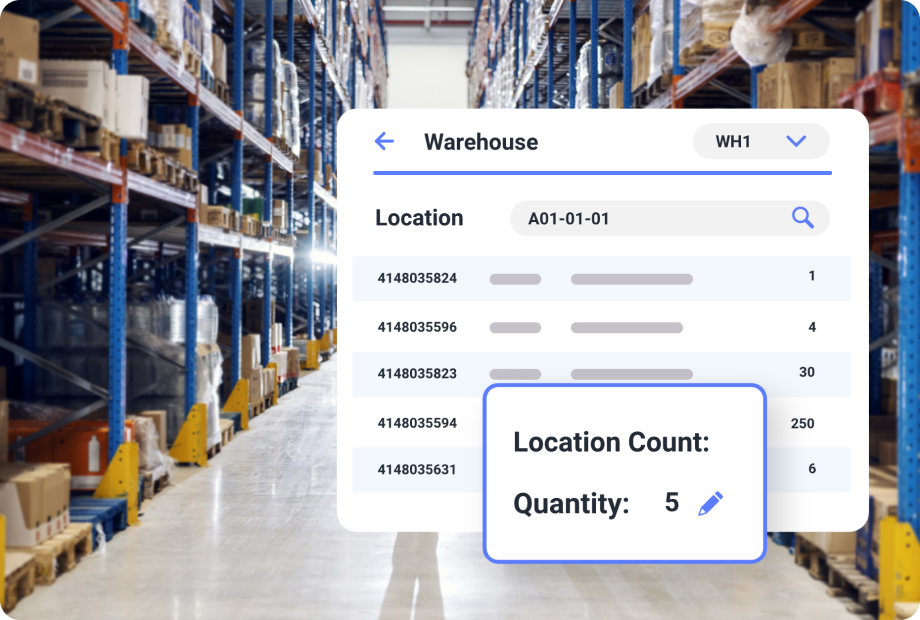

See everything, in real-time

Track and manage inventory data across multiple warehouse and bin locations from a central dashboard for accuracy and ease.

Automatically sync your channels

Update all connected selling channels with the latest inventory availability whenever a new sales or purchase order arrives.

Forecast demand with confidence

Take the guesswork out of demand forecasting and know exactly how much inventory you need to reorder to fulfill orders in the upcoming days or weeks.

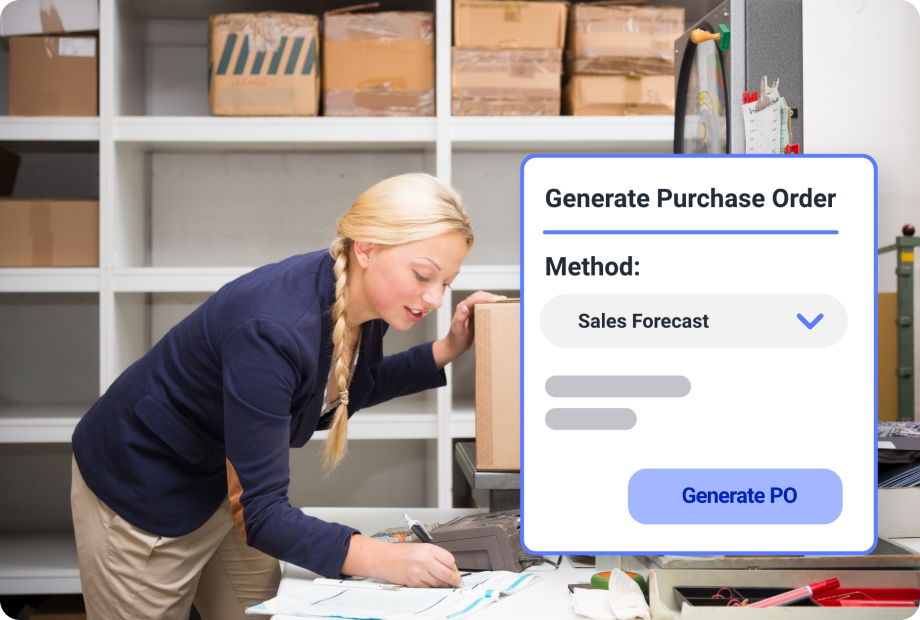

Faster reordering

Save time and reduce manual effort by creating purchase orders at the click of a button to replenish stock to optimal stock levels.

Additional features

Linnworks supports a wide range of inventory management features to fit your workflows from variations, bundles and warehouse transfers to expiry dates tracking and stock levels tracking at 3PL fulfillment centers.

FAQs

Yes, both Linnworks Advanced and SkuVault Core have inventory syncs that will keep your inventory updated on all of your sales channels.

Yes, both Linnworks Advanced and SkuVault Core have features to prevent overselling including inventory syncs, minimum stock levels, and quantity buffers.

A buffer is an adjustment to the quantity that’s shown as available for sale and pushed out to your sales channels.

For example, let’s say Amazon, eBay, and your website are sharing quantities, and you get low, perhaps down to a quantity of one. You may not want to share that last quantity on all of your online marketplaces as it could lead to multiple buyers purchasing on different marketplaces which will result in an oversell.

A quantity buffer on that product communicates the following logic to the system: “If you get down to quantity X (“one” in the above example), then push that quantity to marketplace Y (whichever you choose),” preventing an oversell on other storefronts.

For Linnworks Advanced, inventory view is a user-specific setting, which means that each user will have their own views that do not appear on other users’ inventory screens. This allows each user to customise “My Inventory” in a way that best suits their needs without cluttering the views for other users. Users are able to create, modify or delete views that belong to them.

For SkuVault Core there are twenty different user roles with varying levels of permissions that can be assigned to users. These ensure that the right employees have access to the right information in the software.

Yes. Linnworks has an inventory management feature called Warehouse Transfers. The Warehouse Transfers screen allows you to track the stock movement between two warehouses. This screen uses the concept of transfer cards which shows each stage of the stock journey, starting from being removed from the initial warehouse, being in transit, and then being received at the destination warehouse.

SkuVault Core has a feature called Move/Merge which allows inventory to be transferred between warehouses and locations seamlessly. Each of these movements are tracked down to the user and can be viewed in our Transaction History report.

Yes, Linnworks has an inventory sync that will keep stock updated on all of your sales channels.

Yes. Stock levels automatically update when an order is received and processed from Linnworks. The system sends the new stock amount to all channels that you sell the same item on, reducing the risk of overselling.

Linnworks also has quantity buffers to prevent overselling.

A buffer is an adjustment to the quantity that’s shown as available for sale and pushed out to your sales channels.

For example, let’s say Amazon, eBay, and your website are sharing quantities, and you get low, perhaps down to a quantity of one. You may not want to share that last quantity on all of your online marketplaces as it could lead to multiple buyers purchasing on different marketplaces which will result in an oversell.

A quantity buffer on that product communicates the following logic to the system: “If you get down to quantity X (“one” in the above example), then push that quantity to marketplace Y (whichever you choose),” preventing an oversell on other storefronts.

Yes. Inventory view is a user-specific setting, which means that each user will have their own views that do not appear on other users’ inventory screens. This allows each user to customize “My Inventory” in a way that best suits their needs without cluttering the views for other users. Users are able to create, modify or delete views that belong to them.

There are multiple tools that help you with that. For example:

- In My Inventory, you can right-click on the items and order the items to the Minimum Level threshold or via Smart Calculate (looks at the average of ordered items from the last 3 made purchase orders).

- You can also see from the Open Order screen if you have enough items to fulfill an order. If not, you can create a PO from that screen.

- There is a “Reorder Low Stock” functionality which allows you to order to Minimum Level.

- Then there is Stock Forecasting which uses historical data, seasonality, and other factors to determine how much stock you need to order.

Stock forecasting functionality is available as an add-on to Linnworks Advanced. For more information, please visit our pricing page.